Fortunately, imaging and other non-contact detection technologies solve the problems of users in the medical device industry. Non-contact optical detection technology can quickly collect a large amount of three-dimensional information under the premise of the above-mentioned contact measurement disadvantage, which is sufficient for product development. Data analysis and subsequent workpiece size verification; at the same time, the application of CAD-based measurement software enables users to efficiently and intuitively perform dimensional verification, design analysis and manufacturing process control using 2D\2.5D\3D models.

By integrating multiple types of detection technologies such as image, laser, white light and contact in a single device, the most suitable detection method for different geometries, different materials and different reflective properties and accuracy requirements can be obtained: optical image detection means For measuring the planar size and height dimension of thin and soft workpieces, avoiding deformation caused by direct contact; laser measurement is suitable for rapid measurement and mapping of curved surface contours and common geometric features; white light detection technology is suitable for high precision thin and mirror The surface profile and roughness of the material are measured; the normal trigger detection method is suitable for the measurement of all curved surfaces and geometric features that can be directly contacted.

Therefore, sufficient efficiency and flexibility make the composite image measuring system an ideal solution for small, thin, soft and complex types of geometric surveying and mapping in the medical device industry.

Select OPTIV composite image measuring system

The OPTIV composite image measuring instrument under the Hexagon Industry Group is derived from the upgrade of Mahr and Mycrona multi-sensing measurement technology in Germany. It has several patented technologies, such as 2-Step-Zoom technology, dual CCD design, high-speed amplification, The override switch has no error; the dual Z-axis design allows the Optiv measurement system to maximize the proximity to the measurement entity. For the characteristics of multi-turn parts of medical devices, users can customize the fourth axis turntable that can participate in the calculation online, thereby achieving high-efficiency measurement of rotary parts with multiple positioning angles.

In addition to combining the excellent genes of Mahr and Mycrona multi-sensor technology, the OPTIV composite image measurement system is better optimized by integrating the comprehensive digital measurement software system of the Hexagon Metrology Industry Group, resulting in greater operability and Efficient, low cost and high return.

As the first image measurement software to introduce CAD applications, OPTIV configured PC-DMISVision has powerful CAD application functions, making software operation more efficient and data comparison more intuitive, and its unique multiple feature capture function can be used for the same view. All the features in the field are measured at the same time, which greatly improves the measurement efficiency of feature-intensive workpieces. PC-DMISEMS enterprise-level digital measurement software system can realize the one-click pipeline quality inspection and statistical analysis of massive data on the production line of the factory from the perspective of enterprise digitalization and automation requirements, saving the labor cost of professional quality inspection for the enterprise. And improve the efficiency of quality inspection operations; PC-DMISEMS can also provide multi-port measurement information management and networked reporting system for various departments within the enterprise and even external suppliers of enterprises, ensuring timely adjustment of production and manufacturing at all levels of the enterprise. R&D process, which leads to higher decision-making efficiency; another outstanding advantage of PC-DMIS digital measurement software system is that it provides measurement planning and automatic offline programming module based on the most advanced MBD technology in the world, which can greatly reduce manpower The time to write the test program (about 85% reduction), while eliminating the time required for the measurement device to be occupied, thereby improving the effective detection usage of the measurement device.

Return

Previous article:No

Next article:electronic

- Latest solution

-

-

In recent years, the medical device industry has developed rapidly However, as a typical industry with small siz

-

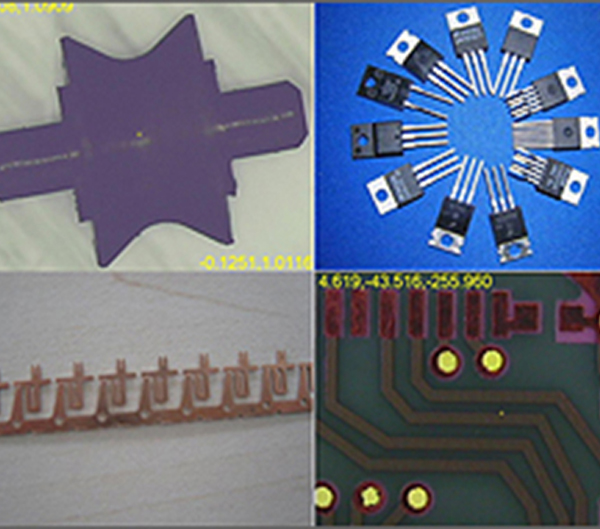

The electronics industry is developing rapidly, with the development of microelectronics-based computers, integrated

-

General equipment manufacturing includes a variety of processing and manufacturing equipment, including a variety of

-

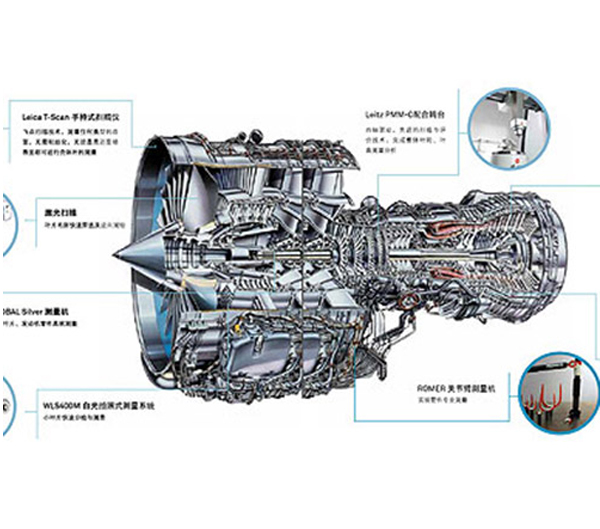

As the heart of the aircraft, aero-engine parts are more complex in geometry and larger in size Typical parts

-

The fuselage of the aircraft is assembled from tens of thousands of parts components, divided into large parts, i

-

If an important part of the core performance of the engine and components, the manufacture of the body is the

-

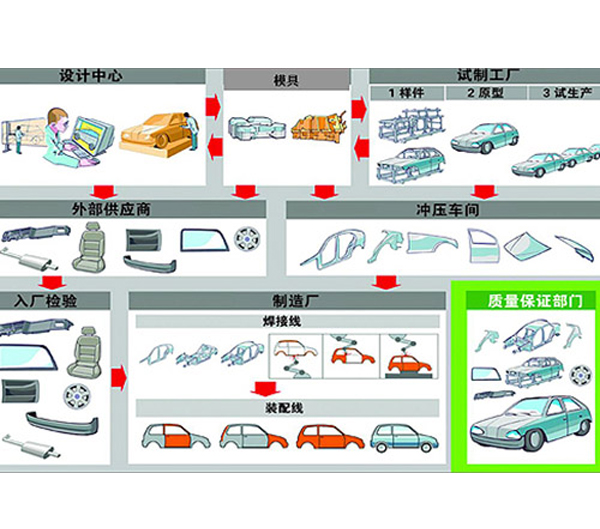

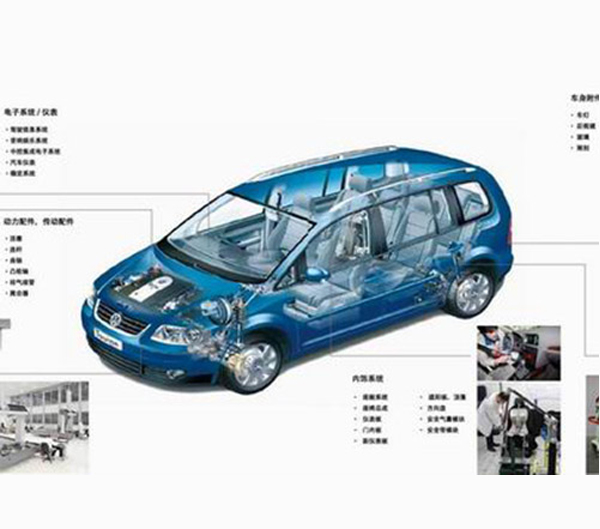

Auto parts have the characteristics of high quality, large batch size and different shapes According to different